Wednesday, January 22, 2020

Monday, January 20, 2020

Thoughts on Bilge Keels (aka Roll Chocks)

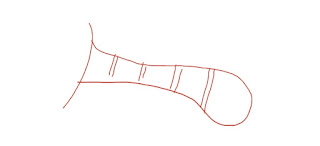

Here are the bilge keel drawings John Niccolls commissioned for Knock Off 37VT66.

A red-lined drawing (i.e. after the fact) would show that Knock Off's bilge keels were installed farther underwater and the forward, aft and distal ends are square, i.e. don't have a parabolic taper.

John Mackie, John William 37VT68 is considering bilge keels and his research has uncovered the following. Concave surfaces on both the top and bottom faces of the bilge keel increase roll resistance (as compared to a flat plate).

Putting holes through the keel will also increase roll resistance. The idea here is that, with properly sized holes, the drag of the water through the length of the hole is greater than the decreased drag because of the hole's presence.

Disrupting the flow at the bilge keel's distal end will also increase roll resistance.

Of the two shapes above it would be interesting to know which is more effective. Certainly increasing the size of the plate, up to an extent, will increase roll resistance.

John Mackie points out that from a one-off, manufacturing perspective, the concave plate with a flat, metal plate on the distal end is easier to make when using glass mat, foam and Marine plywood.

When I last spoke to John M he hoped to make concave keels. The approach will be to sandwich foam around Marine plywood.

The inner layer is ~1" thick plywood while the two outer layers are foam. The whole thing will be encapsulated in fiberglass.

I hope we can keep this conversation going. There's a lot to be learned and I know some tugs that are available as Guinea pigs ;-)

Take care, Dave

Sunday, January 19, 2020

News from Miss Willoughby 37VT05

Above is a picture of him running a tug job as first mate down in Fort Lauderdale. Congratulations on the new position Beau.

And, from Mariah Hicks (Facebook Page):

"Miss Willoughby 37VT05 is officially grubbed. It's happening. IT'S FINALLY HERE!

Beau Hicks & I are leaving early in the morning from Rebel Marina in

Norfolk to head South! Woohoo!!"

Tug Spotting

Take your tug to lunch ~ Titan 37VT31

cruised from Sanford to Astor on the St John River, Florida. She and her crew spent

the night and had dinner at the Blackwater Inn.

Wednesday, January 1, 2020

Weather and Sea State Info...

Dee and Lee Anderson, Jack Robert 37VT17, life long "river rats," who just cruised from Minnesota to Mobile, are on the cusp of their first blue water cruise. Below is a copy of the note I sent them after they asked for advice on weather window timing.

Nellie D. 37VT63's go to site for weather information is passageweather.com. Over the last thirteen years, from Alaska to the Bahamas and on the Great Loop, it kept us out of trouble.

Passage Weather offers all sorts of data but the most important thing for a comfortable trip is the sea state--the graphic titled "Wave Height (m) and direction".

Waves less than 0.5m mean you'll get a very, very comfortable ride.

The chart above predicts perfect big bend weather tommow at 3 UTC, or +4 hrs for CST equals 7am your time. The predominate wave pattern, what little there is of it, is mostly from the southeast or east.

By mousing on the "next" button a bunch of times you can watch what the sea state does over time. In this case the weather window closes fast. By Friday at 4 pm you'd have beam seas up to six feet.

In closing, if you foray out in seas of 0.5m or less, that are predicted to stay that way for more than the duration of your trip, you'll be happy campers.

Dave Howell

Nellie D. 37VT63

Nellie D. 37VT63's go to site for weather information is passageweather.com. Over the last thirteen years, from Alaska to the Bahamas and on the Great Loop, it kept us out of trouble.

Passage Weather offers all sorts of data but the most important thing for a comfortable trip is the sea state--the graphic titled "Wave Height (m) and direction".

Waves less than 0.5m mean you'll get a very, very comfortable ride.

The chart above predicts perfect big bend weather tommow at 3 UTC, or +4 hrs for CST equals 7am your time. The predominate wave pattern, what little there is of it, is mostly from the southeast or east.

By mousing on the "next" button a bunch of times you can watch what the sea state does over time. In this case the weather window closes fast. By Friday at 4 pm you'd have beam seas up to six feet.

In closing, if you foray out in seas of 0.5m or less, that are predicted to stay that way for more than the duration of your trip, you'll be happy campers.

Dave Howell

Nellie D. 37VT63

Tuggers Article -- In the Details: Teak Decks

Tommy Chen and Loren Hart pose by Burmese teak that will be milled and used to build Lord Nelsons.

Our tugs are fortunate to be gilded with teak. This functional, stable, beautiful and now incredibly expensive wood has been used aboard for centuries.

Deck cross section.

Here's a cross section view of an LNVT'S teak deck. A close examination reveals some interesting things. First, the majority of the caulk joint doesn't penetrate all the way through to the underlying fiberglass, but rather rides in a 1/4" square groove. Second, the boards weren't pressed tightly together but rather were spaced 1/32" apart. Third, the black polysulfide caulk was applied into the joint under pressure as the caulk also filled the 1/32" gap between the boards. Forth, the deck boards were quarter sawn (the grain of the wood is perpendicular to the width of the board). Fifth, the teak deck is not a structural part of the boat. Its primary purpose is to act as a non-skid surface.

Growth rings are perpendicular to the board's face in quarter sawn teak. Note the difference in width between winter and summer growth rings.

Side note: Have you ever wondered why some teak boards wear unevenly and become runneled? Teak trees grow year round. As such they have both winter and summer growth rings. Summer growth rings are generally wider and a little softer--meaning they'll erode quicker. In quarter sawn teak, the alternating hard and soft rings run the length of the board. The runneled look along a board's length is simply the result of erosion in the softer wood. This also explains why teak should never be scrubbed along its grain.

Subscribe to:

Posts (Atom)