Thursday, September 27, 2012

Operation of the Velvet Drive's Neutral Switch

The Velvet Drive transmission has a switch on the starboard side which prevents starting the engine in gear. If open, this switch will interrupt the flow of electricity to the engine's starting solenoid. A first step in diagnosing an engine that won't turn over is to check for +12V on both of the switch's connectors.

Sunday, September 23, 2012

What I learned from Jim Backus

By Dave Howell, Nellie D. #63

The person who was involved with the Victory Tug while Jim was doing the preliminary design and part of the final working drawings was a man named Steven Dowdney. It might have been Stephen but Jim tends to think not. He has a company called Rockland Plantation Products somewhere in the Charleston, SC area.

Requirements as defined by the The Society of Naval Architects and Marine Engineers (SNAME) http://www.sname.org/Home/ drove the freeing port design.

Surviving a deadhead strike drove the design thickness of the LNVT's hull.

The hull is designed minimize snap rolling. A snap roll occurs when a heeling hull rapidly returns upright.

Lord Nelson Tugs help put Sundowner tugs out of business.

Jim credits Lindsay Lord's book for the idea of balancing the boat--i.e. keeping it traveling straight through the water--by using both underwater forces on the hull and wind forces on the pilothouse.

William Garden, Bob Perry, and Jim Backus, in that order, were approached by Loren Hart to design the 37 LNVT. After rejecting the designs of Garden and Perry, Bob Perry recommended that Loren talk with Jim Backus. The rest, as they say, is history.

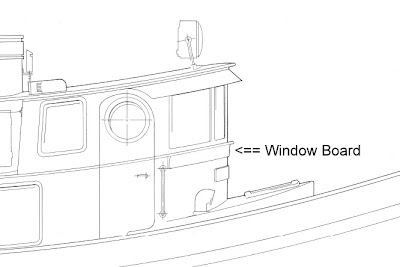

Jim regrets that the board he put under the pilothouse

windows wasn't included on the finished tugs.

Jim Backus' CV

'61 - 62 gets a business degree but moonlights designing houses

'67 - '71 Marines. Works F-4 logistics—mainly fuel supply. Becomes afraid of heights after a helo wind-shear incident.

'71 - gets job as inside salesman for a lumber firm

'72? Enrolls in Westlawn

'73? Gets an engineering job with Pearson Yachts

'75 Marries Helen. Jim and Helen were introduced by Jim's father. Helen was Jim's father's nurse.

'7? Graduates from Westlawn '7 move to Seattle to work for Bob Perry.

7? Left Perry to open his own shop

The person who was involved with the Victory Tug while Jim was doing the preliminary design and part of the final working drawings was a man named Steven Dowdney. It might have been Stephen but Jim tends to think not. He has a company called Rockland Plantation Products somewhere in the Charleston, SC area.

Requirements as defined by the The Society of Naval Architects and Marine Engineers (SNAME) http://www.sname.org/Home/ drove the freeing port design.

Surviving a deadhead strike drove the design thickness of the LNVT's hull.

The hull is designed minimize snap rolling. A snap roll occurs when a heeling hull rapidly returns upright.

Lord Nelson Tugs help put Sundowner tugs out of business.

Jim credits Lindsay Lord's book for the idea of balancing the boat--i.e. keeping it traveling straight through the water--by using both underwater forces on the hull and wind forces on the pilothouse.

William Garden, Bob Perry, and Jim Backus, in that order, were approached by Loren Hart to design the 37 LNVT. After rejecting the designs of Garden and Perry, Bob Perry recommended that Loren talk with Jim Backus. The rest, as they say, is history.

Jim regrets that the board he put under the pilothouse

windows wasn't included on the finished tugs.

Jim Backus' CV

'61 - 62 gets a business degree but moonlights designing houses

'67 - '71 Marines. Works F-4 logistics—mainly fuel supply. Becomes afraid of heights after a helo wind-shear incident.

'71 - gets job as inside salesman for a lumber firm

'72? Enrolls in Westlawn

'73? Gets an engineering job with Pearson Yachts

'75 Marries Helen. Jim and Helen were introduced by Jim's father. Helen was Jim's father's nurse.

'7? Graduates from Westlawn '7 move to Seattle to work for Bob Perry.

7? Left Perry to open his own shop

Saturday, September 22, 2012

Notes from East Coast Tug Talk 2012

Notes from Tug Talk at the East Coast Rendezvous, Sept 22, 2012

1. Some owners are reporting engine overheating failures. The cause could be a blockage in the exhaust, which could cause the muffler to explode. This could be caused by mechanical clamping and pressure over the years. When one blew recently, inspection inside showed PVC buckling and crackling. Suspect that Tommy was using PVC as a form to make the fiberglass pipe.

Here's a guess: Running at normal temp is not a problem for the exhaust. But as temp starts to rise the PVC is melting inside the muffler. As pressure builds up, pushing water out the stern, the PVC could be getting pushed downstream. If you don't see PVC in there, where is it? All our exhaust hoses are getting older, so be sure to inspect when pulled out.

2. Location of mufflers differ.

3. Hull thickness: cutouts from bow thruster show hull thickness is plenty strong. Hjortie and Sally W went one size up, to the size Vetus 95 (8hp).

4. First time tug owner: report from Trev Croteau

Did research on tug handling. Prior boating experience was on low hull boats, like Whalers, @ 50mph.

- Hjortie has a right hand prop. When put into reverse, the stern should go to port, bow to starboard. (The pivot point is at the pilot house.) Learn how to back and fill. (DAVE: a tug with a left hand prop prefers docking on its starboard side)

- Get your head out of the helm. Trev's boat has lots of electronics, and it's easy to become distracted.

- Learn maneuvering in close quarters. Neutral is your best friend. Let her do what she wants to do. Turn the rudder before putting in gear. Keep the bow into the wind or current.

ED: When docking, use one hand on the gear shift lever only, to avoid hitting the throttle.

- Trev likes to use spring lines, not breast lines like most of us, because marinas on the Mississippi River have cleats (that's what he said)

John Isaksen on spring lines: sometimes use the bow line as a spring line. The direction of the tide and wind has a lot to do with how you come in.

- Local knowledge is very important.

THINGS WE'VE LEARNED ABOUT OUR TUGS

John Mackie on fuel tanks. The standard repair is to replace with aluminum. John did it differently. He sandblasted to reveal bad areas; repaired the steel by cutting out the bad stuff and putting in new. Standard costs: new tank: $800 plus labor X4. John's way: $500 for the whole job. John also had a new polyethylene holding tank made to fit in the bow of the boat. Tank work done at a place called Duraweld.

Bob Allnutt: Burns 1.2 gal/hr at 6 knots in still water at 1500-1600 rpm. Has a Yanmar. He upgraded his Alpha Marine auto pilot. Sent it to someone in Washington State to have new works installed. When returned, he noted that a few components were in backwards. The flex gate compass was in reverse. Couldn't get hydraulic pump - had to buy a new one. More trouble that he thought.

Open question: Teak pads on O2 deck are shot. What material is good replacement? Treadmaster is a synthetic decking material that looks like teak. There is synthetic cork. John Taylor prefers teak because it lasts!!!

Lisa and John Taylor: Learned the button in the shower is supposed to turn ON the sump. She spent four hours rewiring to fix something not broken. John dislikes Dahl fuel filters. Hard to change in rolly conditions. Now owns Racor switchover unit. Reinstalled propane system. Pressure water system - all new parts. Air horns are still a mystery. Grub screws in cutlass bearing: if made out of naval brass, will corrode. Learned lots about zincs, found sources and replaced all. Has some weeping water tank access covers. Will replace gaskets.

Marilyn Johnston: A very special boat because of the special people attached to it.

Larry Johnston: This is his fifth boat. All boats are different. Only project: the boat had blisters. Bottom was sandblasted, painted with Interprotect, and then bottom coat. Sandblasting took off more than expected. Did not put fiberglass back on. Put on Interlux 2000.

WHY DO SOME BOATS BLISTER AND OTHERS NOT?

If the boat hasn't blistered, it probably won't. Tommy said the resins were causing problems; came in 55 gallon drums; probably used different brands.

Garry said that a fire retardant put into the resin could have caused blisters.

Why, after applying Interlux 2000 did blister appear? John Mackie: surface wasn't dry enough.

To determine if dry: put tape over blister. If you find water under the tape after two days, it's not dry enough.

Ed: when boats have poor gelcoat, water leaks out; no blisters when boats have good gelcoat water is trapped and blisters will appear.

Trev Croteau: About to ship his tug from the Chesapeake to the Tennessee River and travel north to home in Minneapolis. Surprised how much it can suck up money. Nothing has really surprised him.

Stephanie Croteau: The tug is going to be a new adventure. Glad she came to the rendezvous. Slept aboard for first time last night.

Ed McChain: Work with Tommy door opening. Engine room hatch left open and wife Mary Ann fell through.

Mary Ann McChain: It was emotionally hard to sell their sailboat. They plan to cruise south this winter and north next summer. The boat is comfortable; dogs love it.

Barb: Learned to chant "Neutral is a gear." She uses the head in the sand approach. Most learning from noise or smell; waits for something to happen and then acts. Wants to take a more proactive approach. Planning to truck her tug to a friend's house two hours away. Big cosmetic and mechanical overhaul during the winter. "These boats need to be used." Bought her boat in seven days from first seeing on the web. Tug has unique superstructure: radar arch.

AllanSeymour: What made the Mini Loop trip special was the people met. Jim Backus made an object which makes people smile. Great attraction.

John and Ellen Isaksen: Added to Allan's comments on popularity of the LNVT. Experiences with open house in New Bedford; many people came on board and raved. The tug is very relaxing. Have company a lot. The people they've met through the association has had a great impact.

Key Stage: His fuel management plan, don't go anywhere. Stay tied to the dock. Three issues: Boat stored on trickle charge. LONG STORY. Conclusion: Smart chargers aren't smart. Struggling with Raymarine for 5 years. Problem was his Raystar 120 antenna. He rewired, put in a new GS 130 GPS and it works perfectly. Boat farts. Foul smell on boat traced to the kitchen sink. Effluent flushed from the toilet displaces air in the black water tank. A common vent with the gray water allows this tank to be over pressurized allowing foul air to backup into the kitchen sink. Bottom line: don't common vent gray and black water tanks.

Clara: So impressive. The passion is contagious. Dave and Key are great teachers.

Garry and Carol Domnisse: Installed solar power to LNVT. One solar panel keeps trickle charge on 8D batteries. Need solar controller to make sure not overcharging. Great when on a mooring; no need for wind generator.

1. Some owners are reporting engine overheating failures. The cause could be a blockage in the exhaust, which could cause the muffler to explode. This could be caused by mechanical clamping and pressure over the years. When one blew recently, inspection inside showed PVC buckling and crackling. Suspect that Tommy was using PVC as a form to make the fiberglass pipe.

Here's a guess: Running at normal temp is not a problem for the exhaust. But as temp starts to rise the PVC is melting inside the muffler. As pressure builds up, pushing water out the stern, the PVC could be getting pushed downstream. If you don't see PVC in there, where is it? All our exhaust hoses are getting older, so be sure to inspect when pulled out.

2. Location of mufflers differ.

3. Hull thickness: cutouts from bow thruster show hull thickness is plenty strong. Hjortie and Sally W went one size up, to the size Vetus 95 (8hp).

4. First time tug owner: report from Trev Croteau

Did research on tug handling. Prior boating experience was on low hull boats, like Whalers, @ 50mph.

- Hjortie has a right hand prop. When put into reverse, the stern should go to port, bow to starboard. (The pivot point is at the pilot house.) Learn how to back and fill. (DAVE: a tug with a left hand prop prefers docking on its starboard side)

- Get your head out of the helm. Trev's boat has lots of electronics, and it's easy to become distracted.

- Learn maneuvering in close quarters. Neutral is your best friend. Let her do what she wants to do. Turn the rudder before putting in gear. Keep the bow into the wind or current.

ED: When docking, use one hand on the gear shift lever only, to avoid hitting the throttle.

- Trev likes to use spring lines, not breast lines like most of us, because marinas on the Mississippi River have cleats (that's what he said)

John Isaksen on spring lines: sometimes use the bow line as a spring line. The direction of the tide and wind has a lot to do with how you come in.

- Local knowledge is very important.

THINGS WE'VE LEARNED ABOUT OUR TUGS

John Mackie on fuel tanks. The standard repair is to replace with aluminum. John did it differently. He sandblasted to reveal bad areas; repaired the steel by cutting out the bad stuff and putting in new. Standard costs: new tank: $800 plus labor X4. John's way: $500 for the whole job. John also had a new polyethylene holding tank made to fit in the bow of the boat. Tank work done at a place called Duraweld.

Bob Allnutt: Burns 1.2 gal/hr at 6 knots in still water at 1500-1600 rpm. Has a Yanmar. He upgraded his Alpha Marine auto pilot. Sent it to someone in Washington State to have new works installed. When returned, he noted that a few components were in backwards. The flex gate compass was in reverse. Couldn't get hydraulic pump - had to buy a new one. More trouble that he thought.

Open question: Teak pads on O2 deck are shot. What material is good replacement? Treadmaster is a synthetic decking material that looks like teak. There is synthetic cork. John Taylor prefers teak because it lasts!!!

Lisa and John Taylor: Learned the button in the shower is supposed to turn ON the sump. She spent four hours rewiring to fix something not broken. John dislikes Dahl fuel filters. Hard to change in rolly conditions. Now owns Racor switchover unit. Reinstalled propane system. Pressure water system - all new parts. Air horns are still a mystery. Grub screws in cutlass bearing: if made out of naval brass, will corrode. Learned lots about zincs, found sources and replaced all. Has some weeping water tank access covers. Will replace gaskets.

Marilyn Johnston: A very special boat because of the special people attached to it.

Larry Johnston: This is his fifth boat. All boats are different. Only project: the boat had blisters. Bottom was sandblasted, painted with Interprotect, and then bottom coat. Sandblasting took off more than expected. Did not put fiberglass back on. Put on Interlux 2000.

WHY DO SOME BOATS BLISTER AND OTHERS NOT?

If the boat hasn't blistered, it probably won't. Tommy said the resins were causing problems; came in 55 gallon drums; probably used different brands.

Garry said that a fire retardant put into the resin could have caused blisters.

Why, after applying Interlux 2000 did blister appear? John Mackie: surface wasn't dry enough.

To determine if dry: put tape over blister. If you find water under the tape after two days, it's not dry enough.

Ed: when boats have poor gelcoat, water leaks out; no blisters when boats have good gelcoat water is trapped and blisters will appear.

Trev Croteau: About to ship his tug from the Chesapeake to the Tennessee River and travel north to home in Minneapolis. Surprised how much it can suck up money. Nothing has really surprised him.

Stephanie Croteau: The tug is going to be a new adventure. Glad she came to the rendezvous. Slept aboard for first time last night.

Ed McChain: Work with Tommy door opening. Engine room hatch left open and wife Mary Ann fell through.

Mary Ann McChain: It was emotionally hard to sell their sailboat. They plan to cruise south this winter and north next summer. The boat is comfortable; dogs love it.

Barb: Learned to chant "Neutral is a gear." She uses the head in the sand approach. Most learning from noise or smell; waits for something to happen and then acts. Wants to take a more proactive approach. Planning to truck her tug to a friend's house two hours away. Big cosmetic and mechanical overhaul during the winter. "These boats need to be used." Bought her boat in seven days from first seeing on the web. Tug has unique superstructure: radar arch.

AllanSeymour: What made the Mini Loop trip special was the people met. Jim Backus made an object which makes people smile. Great attraction.

John and Ellen Isaksen: Added to Allan's comments on popularity of the LNVT. Experiences with open house in New Bedford; many people came on board and raved. The tug is very relaxing. Have company a lot. The people they've met through the association has had a great impact.

Key Stage: His fuel management plan, don't go anywhere. Stay tied to the dock. Three issues: Boat stored on trickle charge. LONG STORY. Conclusion: Smart chargers aren't smart. Struggling with Raymarine for 5 years. Problem was his Raystar 120 antenna. He rewired, put in a new GS 130 GPS and it works perfectly. Boat farts. Foul smell on boat traced to the kitchen sink. Effluent flushed from the toilet displaces air in the black water tank. A common vent with the gray water allows this tank to be over pressurized allowing foul air to backup into the kitchen sink. Bottom line: don't common vent gray and black water tanks.

Clara: So impressive. The passion is contagious. Dave and Key are great teachers.

Garry and Carol Domnisse: Installed solar power to LNVT. One solar panel keeps trickle charge on 8D batteries. Need solar controller to make sure not overcharging. Great when on a mooring; no need for wind generator.

Tuesday, September 11, 2012

6mm Glass and Cummins Tripod vs. Four-point Mount

While aboard Hjortie #33 yesterday I noticed that the pilothouse drop down windows appeared thinner than 10mm. Also that the waterlift muffler is like Nellie's #63 (i.e. vertically mounted just aft and starboard of the engine and in a space cutout of the starboard water tank). The tripod front engine mount is identical to Titan #31, Sally W. #42, and Knock Off #66. By the time Nellie was built the engine's tripod mount had been replaced with conventional corner engine mounts. Hjortie has a second pilothouse-to-engineroom floor board, that doesn't appear to be factory installed, directly over the engine. I assume this was put in to facilitate the new engine installation.

Monday, September 10, 2012

Muffler and Bilge Pump Configurations, Pilothouse Glass Thickness

What I learned at the PNW Rendezvous

By Dave Howell, Nellie D. #63

There are at least two waterlift muffler configurations. Earlier tugs (including Titan #30 and Sally W. #42) have a muffler where the inlet is on one side of the can and the outlet is on the other. The muffler is attached under the floor boards and inboard of the starboard water tank. On later tugs (Pet Tug #60 and Nellie D. #63) the muffler's inlet and outlet are both on the top side. The muffler sits in a cutout part of the water tank's inboard, forward section. The latter is a much more complex and costy installation—I can only think that it was for functional reasons the change was made. How quickly the exhaust hose heats up very when raw water flow stops. I could barely keep my hand on Pet Tugs 3" exhaust hose, a foot or so aft of the muffler, meaning it had reached ~115F in the short period between muffler explosion and engine shutdown.

In the past week I saw two tugs with bilge pumps forward of the engine and with their respective float switches mounted on top of the pump. Was this where and how the factory installed the pumps? If so, it doesn't make a lot of sense as the deepest point in an LNVT's bilge is under the packing gland. This pump won't turn on until the engine's pan is well under water.

In a conversation with Sally and Allan Seymour, aboard the Sally W. #42, Jim Backus suspected that the glass in the two pilot house lowering windows was thinner than the 10mm saftey glass he'd specified. I believe that Nellie's glass in these two windows is also less than 10mm and probably it's true of the rest of the fleet too. So, why are the drop down windows in the pilothouse 5mm (I'm guessing) when they were specified to be 10mm? Perhaps it's because the factory thought the weight of 10mm glass would be too heavy lift and opted for 5mm. So what's the weight difference? Glass weight (exclusive of the wood frame) in a 10mm pilothouse drop down window is 14 lbs and 7 lbs for 10 mm glass. It doesn't seem like a 7 lb difference is worth it considering the safety compromise. But as both Allan and Sally on Sally W. point out, 7 lbs is a lot especially when reaching all the way across the starboard side's chart table. The numbers to support the calculations: 1. 10mm glass weights around 5 lbs/ft^2 2. 5mm weighs 2.5 lbs/ft^2 3. Pilothouse drop down window glass measurement is: 17-1/2" x 23-1/4" or 2.9 ft^2 (per Sally W. #42)

By Dave Howell, Nellie D. #63

There are at least two waterlift muffler configurations. Earlier tugs (including Titan #30 and Sally W. #42) have a muffler where the inlet is on one side of the can and the outlet is on the other. The muffler is attached under the floor boards and inboard of the starboard water tank. On later tugs (Pet Tug #60 and Nellie D. #63) the muffler's inlet and outlet are both on the top side. The muffler sits in a cutout part of the water tank's inboard, forward section. The latter is a much more complex and costy installation—I can only think that it was for functional reasons the change was made. How quickly the exhaust hose heats up very when raw water flow stops. I could barely keep my hand on Pet Tugs 3" exhaust hose, a foot or so aft of the muffler, meaning it had reached ~115F in the short period between muffler explosion and engine shutdown.

In the past week I saw two tugs with bilge pumps forward of the engine and with their respective float switches mounted on top of the pump. Was this where and how the factory installed the pumps? If so, it doesn't make a lot of sense as the deepest point in an LNVT's bilge is under the packing gland. This pump won't turn on until the engine's pan is well under water.

In a conversation with Sally and Allan Seymour, aboard the Sally W. #42, Jim Backus suspected that the glass in the two pilot house lowering windows was thinner than the 10mm saftey glass he'd specified. I believe that Nellie's glass in these two windows is also less than 10mm and probably it's true of the rest of the fleet too. So, why are the drop down windows in the pilothouse 5mm (I'm guessing) when they were specified to be 10mm? Perhaps it's because the factory thought the weight of 10mm glass would be too heavy lift and opted for 5mm. So what's the weight difference? Glass weight (exclusive of the wood frame) in a 10mm pilothouse drop down window is 14 lbs and 7 lbs for 10 mm glass. It doesn't seem like a 7 lb difference is worth it considering the safety compromise. But as both Allan and Sally on Sally W. point out, 7 lbs is a lot especially when reaching all the way across the starboard side's chart table. The numbers to support the calculations: 1. 10mm glass weights around 5 lbs/ft^2 2. 5mm weighs 2.5 lbs/ft^2 3. Pilothouse drop down window glass measurement is: 17-1/2" x 23-1/4" or 2.9 ft^2 (per Sally W. #42)

Monday, August 27, 2012

LNVT Muffler Issues

A handful of tugs have reported problems associated with the muffler. Today I got to see a failure firsthand when Pet Tug #60's muffler split apart while the tug was underway. The split occurred along the fiberglassed joint between the unit's top and bottom halves. According to Lou Steplock, there was a loud bang and oily water went everywhere in the engine room. After the muffler was removed only a little bit of fiberglass held its two halves together--resembling something like the hinge on a clam shell. Not much effort was required to get the halves apart. Once apart several things became clearer. The fiberglass tubes, which the exhaust hoses attach to, we're formed around what appears to be PVC. As the picture shows, Pet Tugs' PVC was deforming and small pieces of burnt PVC were found in freely floating inside the muffler.

On Pet Tug #60, where the normal sink and stove positions are swapped, i.e. stove inboard and sink outboard, the galley width is 1" and the Tommy door is 1" deeper.

On Pet Tug #60, where the normal sink and stove positions are swapped, i.e. stove inboard and sink outboard, the galley width is 1" and the Tommy door is 1" deeper.

Wednesday, July 18, 2012

What I Learned from Ed McChain

What I learned from Ed McChain, Thistle #47

By Dave Howell, Nellie D. #63

1. By rotating the Dutch door's exterior escutcheon 120 degrees, the door handle can't vibrate itself open--and thus the door hooks aren't required. This not only makes the doors safer but easier to use too.

2. Getting aboard an LNVT from the water is problematic. Using the engine room's ladder on the bulwark's exising pintles is not really satisfactory because (1) the ladder doesn't go far enough into the water and (2) it's hard to climb the ladder's negative slope. Ed bought a marine ladder and then made a PVC adapter to mate the ladder to the existing Pintles.

3. To cool the engine room Ed installed a ducted fan near the ceiling and then vented it by drilling a new hole in the cabin side just aft of the existing portside engine room grille. He could have used the existing engine room vent but feared he'd diminish the little natural airflow that already exists. Using the ducted fan reduces the engine room's ambient temperature by 20F.

4. If you want to know what dinghy handling systems really work, talk to a pet owner that likes to anchor out. Ed takes his two pups ashore regularly using his 8' sailing dinghy and 2hp (?) engine. I watched him singlehandedly stow the dink, with the engine attached, on the O2 deck, in a total of two minutes, using an electrically powered davit. The davit is mounted to the port, aft corner of the salon. it's tall enough to lift the dink over the O2 deck's lifelines. Ed estimates the dink weighs around 200 pounds. The dink sits on chocks just aft of the companionway hatch. There wasn't any noticeable heeling of Thistle as the dink was lifted.

By Dave Howell, Nellie D. #63

1. By rotating the Dutch door's exterior escutcheon 120 degrees, the door handle can't vibrate itself open--and thus the door hooks aren't required. This not only makes the doors safer but easier to use too.

2. Getting aboard an LNVT from the water is problematic. Using the engine room's ladder on the bulwark's exising pintles is not really satisfactory because (1) the ladder doesn't go far enough into the water and (2) it's hard to climb the ladder's negative slope. Ed bought a marine ladder and then made a PVC adapter to mate the ladder to the existing Pintles.

3. To cool the engine room Ed installed a ducted fan near the ceiling and then vented it by drilling a new hole in the cabin side just aft of the existing portside engine room grille. He could have used the existing engine room vent but feared he'd diminish the little natural airflow that already exists. Using the ducted fan reduces the engine room's ambient temperature by 20F.

4. If you want to know what dinghy handling systems really work, talk to a pet owner that likes to anchor out. Ed takes his two pups ashore regularly using his 8' sailing dinghy and 2hp (?) engine. I watched him singlehandedly stow the dink, with the engine attached, on the O2 deck, in a total of two minutes, using an electrically powered davit. The davit is mounted to the port, aft corner of the salon. it's tall enough to lift the dink over the O2 deck's lifelines. Ed estimates the dink weighs around 200 pounds. The dink sits on chocks just aft of the companionway hatch. There wasn't any noticeable heeling of Thistle as the dink was lifted.

Tuesday, July 17, 2012

Cummins 4BT-3.9M 150hp Fuel Consumption

Data came from a newly installed Flowscan on Hjortie #33. As a sanity check Hjortie's data is compared to Nellie D's #63 data which was collected last year.

| RPM | Hull 33 | Hull 63 |

|---|---|---|

| 1200 | .7 | .9 |

| 1400 | 1.1 | 1.2 |

| 1600 | 1.4 | 1.6 |

| 1700 | 1.7 | 1.7 |

| 1750 | 1.8 | |

| 1800 | 2.0 | 1.9 |

| 1950 | 2.4 | |

| 2000 | 2.5 | 2.8 |

| 2200 | 4.0 | 3.6 |

Monday, February 27, 2012

List of Known LNVT Issues

The following is a partial list of issues which LNVTs may face sometime during their lifetimes:

- Replace BMW diesel ($18,000)

- Fuel tank replacement ($12,000 or $5,000 DIY)

- Window channel replacement ($150 DIY)

- Window frame rebed ($50 DIY)

- Cummins exhaust elbow replacement ($1,800 or $1,600 DIY)

- Turbocharger rebuild ($1,600)

- Replace 3" wet exhaust hose ($300 DIY)

- Rebuild diesel injector pump ($400 DIY)

- Replace stainless water tank lid parts with plastic ($100 DIY)

- Bulwark gel coat crack repair

It would be good to expand this list to all known issues.

Subscribe to:

Posts (Atom)